Platform Introduction

IPS is short for Industrial Path Solution , It’s developed by Fraunhofer-Gesellschaft , which is the biggest organization for applied research and development services in Europe. ,and it initiate and advocate Industry 4.0 in Germany . IPS is the achievement of Fraunhofer’s technology meeting industry ,base on math , mechanics and computer science ,aims to provide digital simulation solutions for such as flexible components , assembly verification, ergonomics and robot cooperation . There are more than 90 users of IPS all over the world ,and it spreads over industrial area, like Automobile ,3C ,Aviation, Aerospace, Rail and so on.

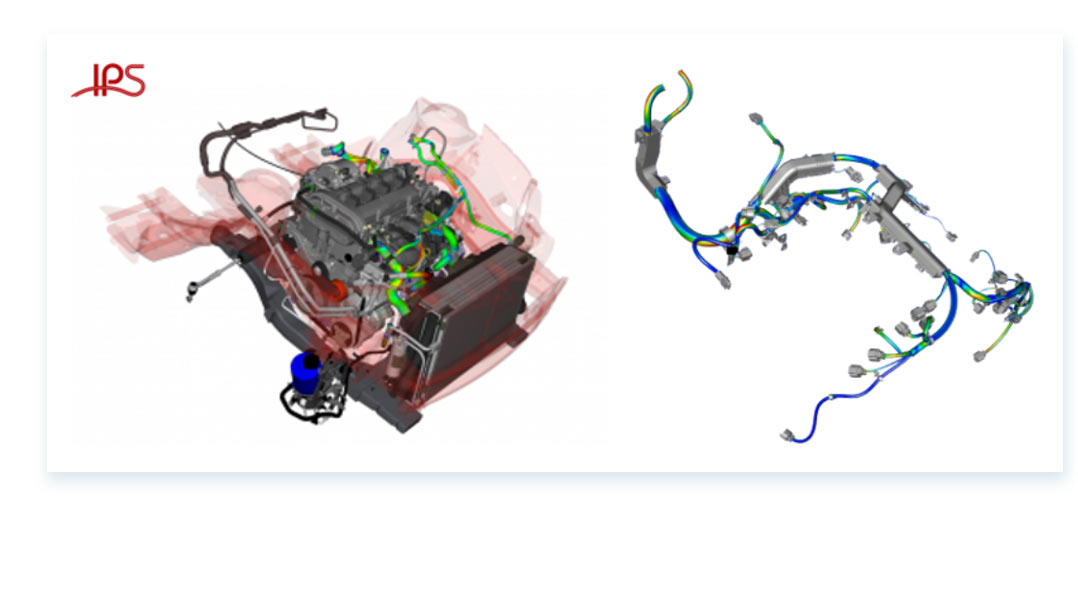

• IPS Cable Simulation has unique selling propositions in the field of automotive and industrial process optimization and quality assurance with respect to cables ,wiring harness and hoses, The software has been successfully evaluated into the product process of various automotive companies as standard tool for digital mock-up with flexible components. Moreover IPS Cable Simulation is integrated into process as fast interdisciplinary decision platform. Thus, validated results may be achieved 6 to 8 months earlier.

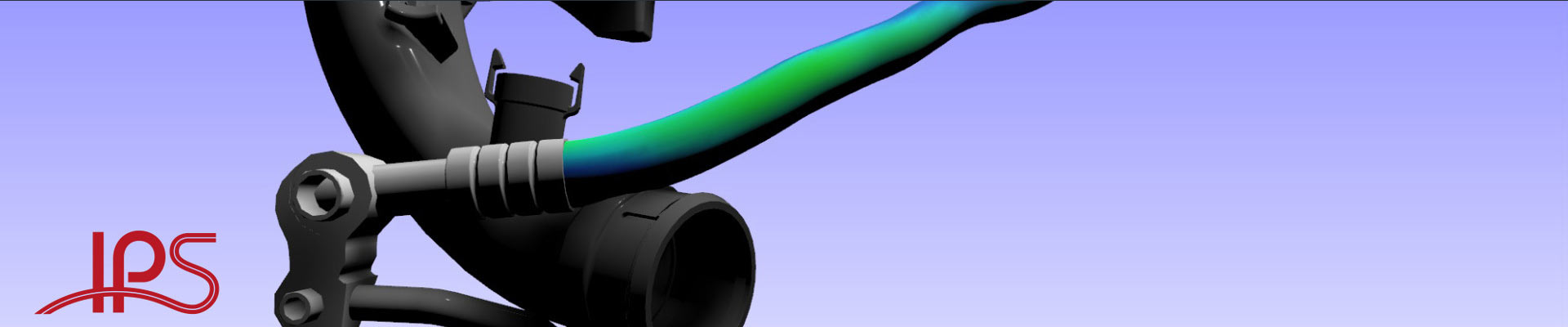

• Consideration of realistic material properties and gravity , cables, hoses and harnesses are flexible,

• Motion analysis of flexible components in constructed space and the external force,

• No need to mesh ,simulation and analysis in real-time,

• Generating envelopes to verify the reliability of design involved into tolerance,

• Dynamic clips and connections (including clip database),

• Dynamic and Durability analysis,

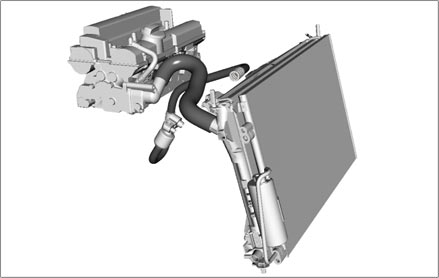

• Pressurized hoses ,preformed hose ,grommet, flat cable,

• Adjustment and interactive optimization of flexible parts and clips .

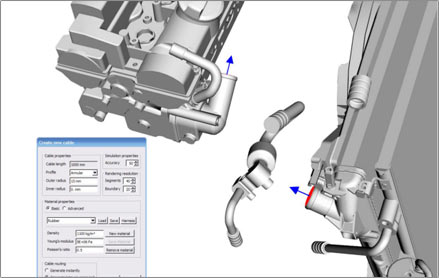

Step 1:Define

There are three possibilities of defining a wire: Creating an initial cable instantly, using the Automatic Routing feature or providing a pre-deformed shape by inserting a curve.

Step 2:Connect

The locations for fastening cable clips and clip connections need to be defined. After that the cable can be connected with any object and/or other cables.

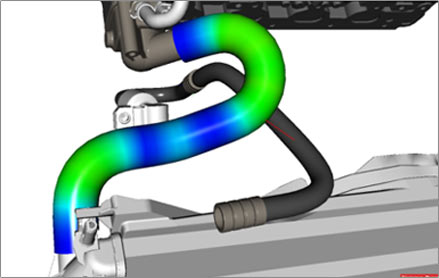

Step 3:Visualize

The stress and strain in the wire are visualized by color coding, and it is possible to set up and monitor critical distance and value measurements.

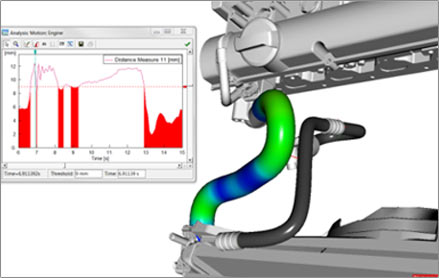

Step 4:Analyze

The object motions can be imported from XMO. They provide a basis for the analysis of the wire’s motions with respect to the critical measurements. An envelope of the motion can also be created.