Platform Introduction

3DCS - Three-Dimensional Deviation Analysis Specialist——Graphical tolerance simulation software.3DCS is the most advanced dimensional deviation analysis tool used to simulate the design, manufacture and assembly of the product, predicting the amount of deviation inherent in the design and determining the source of the deviation.3DCS provides the necessary tolerance analysis methods to predict process changes in an assembly ,identifies the source of additional changes and improves the stableness of the design.ultimately,enabling users to analyze and optimize designs to improve quality and reduce costs early in the design phase.

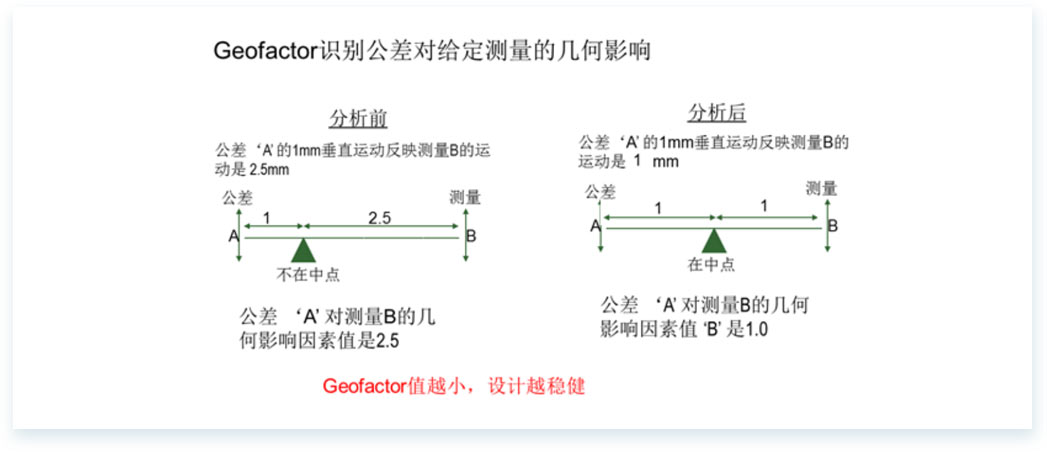

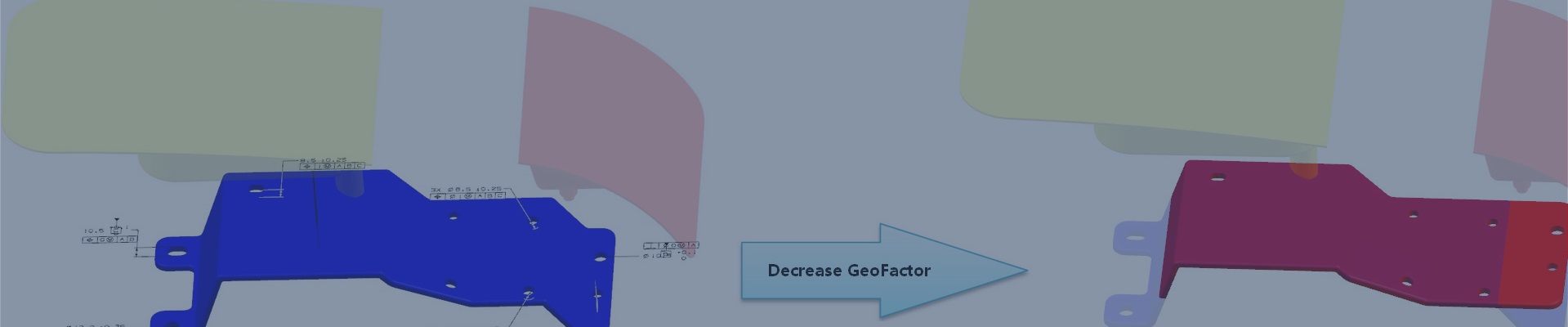

• 3DCS Geofactor Analyzer determines whether a change in tolerance is sensitive to product assembly results,that is, whether a slight change may result in a significant change in assembly results.Sensitivity is determined by products assembly positioning and geometry.This geometric relationship is represented by a coefficient, which called GeoFactor (geometric influence factor), showing the amplification effect of assembly positioning and geometric structure on deviation.

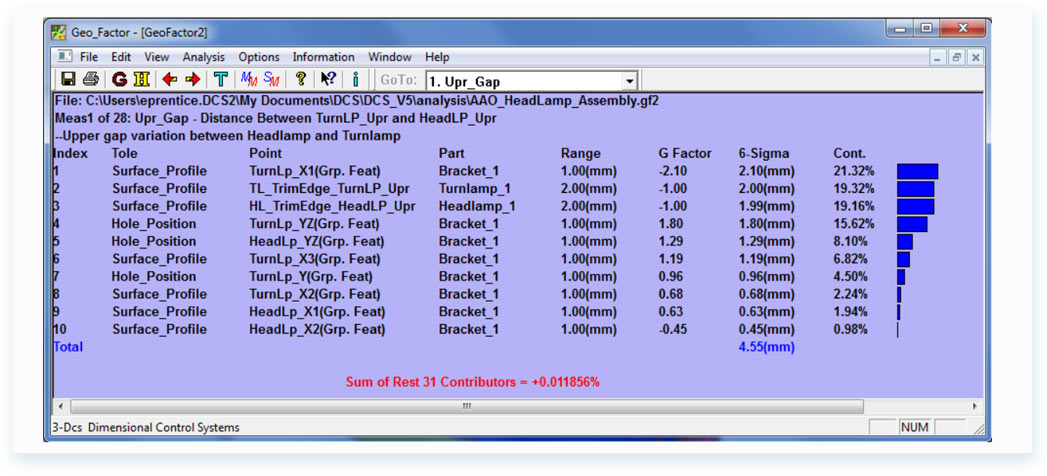

• Provide Geofactor or influence coefficients.

• The coefficient reflects the true tolerance effect.

• Reflects how the tolerance is magnified by the geometry of the parts.

• Focus on the stableness of the design rather than the tolerances.

• Provide numerical results for design validation;

• 3DCS Geofactor Analysis: Determine magnification factors for each tolerance.

ØHow does tolerance change affect assembly quality—If a tolerance is Increase or decrease, determine how much it affects the assembly results.

ØHow does product structure and positoning affect assembly quality—Determine how the assembly process affects the effect of tolerances.

• Check the geometric effects of tolerances—Determine the amplification effect of geometric structure on tolerance based on the geometry of conponents.

ØGeoFactor is greater than 1, tolerance is magnified.

ØGeoFactor is less than 1 , the tolerance is reduced.